News

Power Space tailor-made dust removal plan for you

Components and Functions of Laser Fume Extractors

Laser cutting fume extractions play a crucial role in maintaining air quality and worker safety in environments where laser cutting or plasma cutting operations generate harmful smoke and fumes. Understanding the key components and their functions is essential for efficient operation and maintenance of these systems. There are 4 parts of laser cutting fume extractions:

Filter Catridge

Automatic Cleaning System

Pressure Gauge

Oil-Water Separator

Filter Cartridge of Laser Fume Extraction

The filter cartridge is designed to adsorb and filter smoke and fumes generated during laser cutting or plasma cutting processes. The LW12 series laser fume extractor employs high-quality Ahlstrom nano-flame-retardant filter cartridges, known for their excellent filtration and flame-retardant properties. Filter cartridge replacement intervals typically range from 1 to 2 years, depending on specific usage conditions and maintenance practices.

Automatic Cleaning System of Laser Fume Extraction

The pulse control unit is responsible for managing the pulse backwash of the filter cartridge in the laser cutting fume extractor. It regulates parameters such as blow time, intervals, cycles, and output channels. This component is pivotal in optimizing the cleaning efficiency of the filter cartridge, directly impacting the overall effectiveness and lifespan of the laser fume extractor.

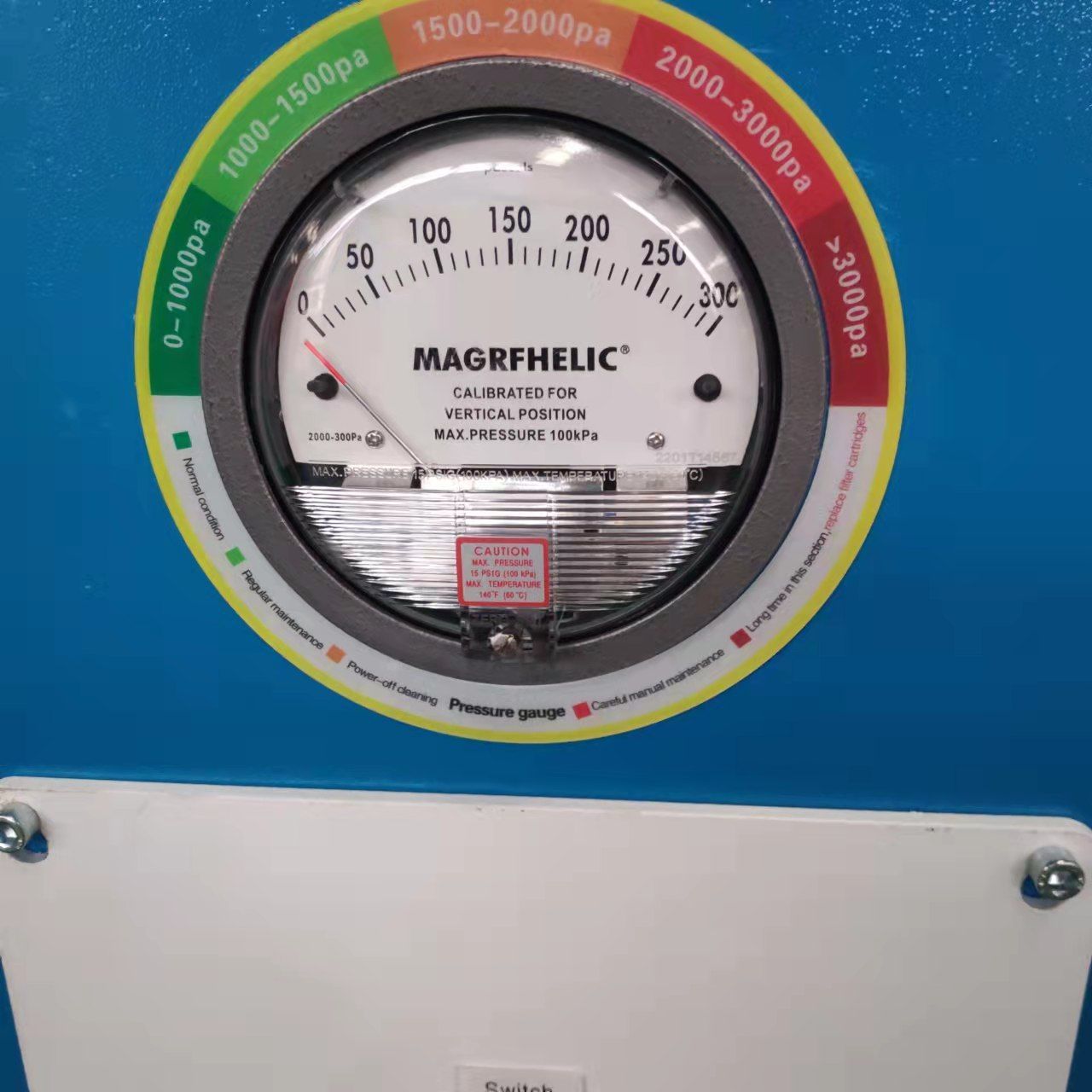

Pressure Gauge of Laser Fume Extraction

The purpose of the pressure gauge is to measure the pressure differential inside and outside the filter cartridge of laser fume extraction. It serves as an indicator of the filter cartridge's clogging level. Generally, a higher pressure differential signifies increased clogging. Specific cleaning methods corresponding to pressure differentials are recommended based on manufacturer guidelines. More details, you can read Maintenance Guide for Laser Fume Extractors .

Oil-Water Separator of Laser Fume Extraction

The oil-water separator provides clean compressed air for the automatic pulse cleaning process of the laser fume extractor. It ensures that the compressed air remains free of moisture, preventing corrosion in the pulse cleaning system. Any water vapor present in the compressed air is promptly drained through the drainage outlet, safeguarding the integrity of the system.

How to Maintain Laser Fume Extractors

Here are some tips on how to maintain laser fume extractors, ensuring they operate effectively and efficiently.

1.Daily Inspections: Check the fume extractor before each use for any visible damage, unusual noises, or signs of wear. Ensure that all connections are secure and that the system is operating correctly.

2.Filter Maintenance: The heart of the fume extractor is its filter system. Here's how to maintain it:

a.Pre-Filters: These should be checked and cleaned or replaced regularly, depending on usage. A clogged pre-filter can reduce airflow and the efficiency of the main filter.

b.Main Filters: Depending on the type (cartridge or HEPA), main filters should be replaced according to the manufacturer's recommended schedule. A pressure gauge can indicate when the filter needs changing.

3.Cleaning: Clean the exterior of the fume extractor with a damp cloth to remove dust and debris. For internal components, follow the manufacturer's cleaning instructions to avoid damaging sensitive parts.

Conclusion

Understanding and maintaining the key components of laser fume extractors are vital for ensuring optimal filtration efficiency, prolonged equipment lifespan, and a safe working environment in facilities utilizing laser cutting or plasma cutting technologies. If you need further details or specific maintenance instructions, feel free to ask!