News

Power Space tailor-made dust removal plan for you

10 Tips of Welding Fume Extractor Maintenance

Maintaining a welding fume extractor is crucial for ensuring its efficiency, longevity, and the safety of the welders and other workers in the area. Here are 10 tips on how to maintain a welding fume extractor:

Regular Inspections of Welding Fume Extraction

Inspect the weld fume extractor regularly for any signs of wear, damage, or blockages.

Check all electrical connections to ensure they are secure and in good condition.

Look for any leaks in the ductwork or the filter housing.

Filter Maintenance of Welding Fume Extraction

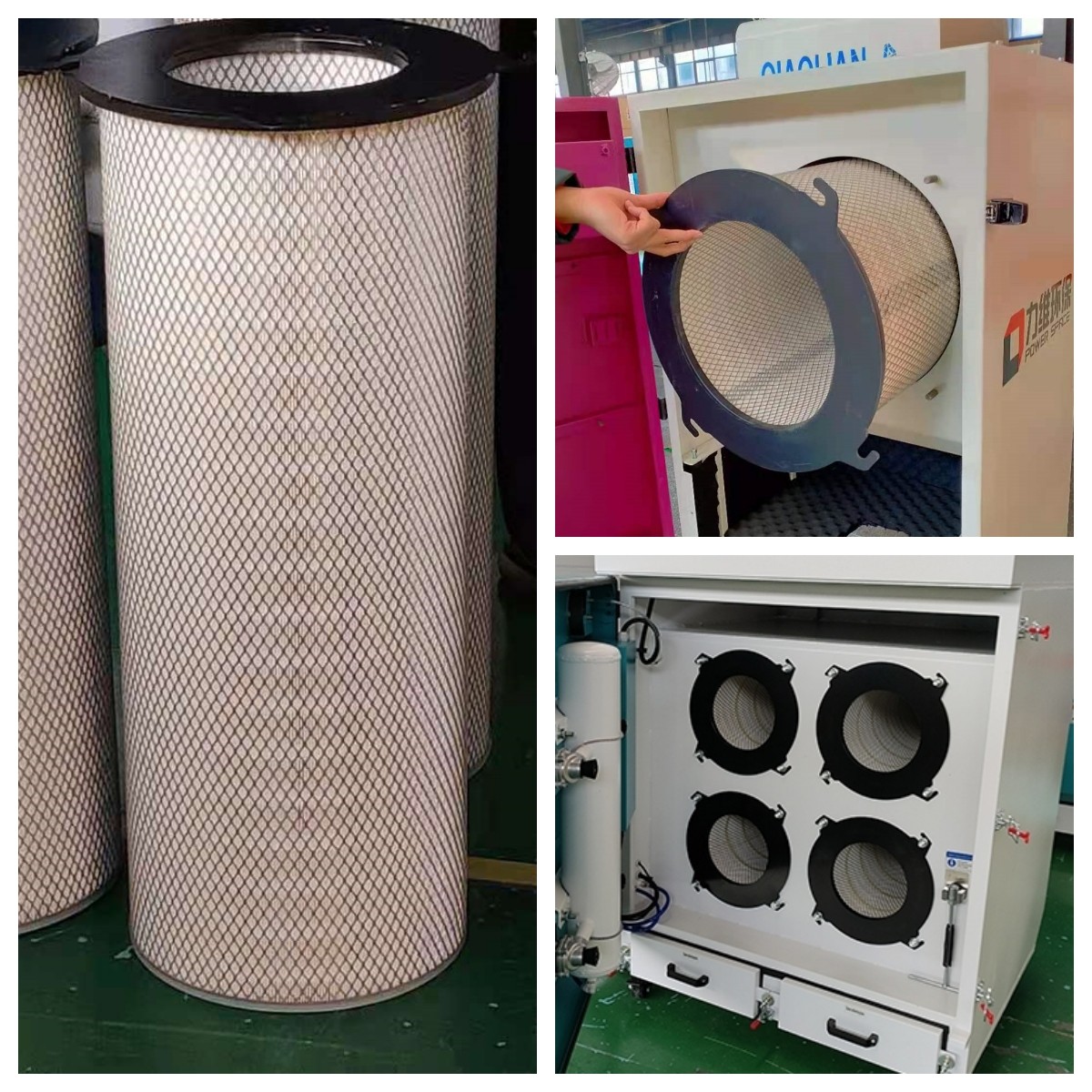

The filters are one of the most important parts of the welding fume extractor. Clean or replace the filters according to the manufacturer's recommendations.

For pre-filters, cleaning can often be done by vacuuming or washing with water (if they are water-resistant).

For main filters (HEPA or similar), they are typically disposable and will need to be replaced when they reach their recommended lifespan or when airflow is significantly reduced.

Cleaning of Welding Fume Extraction

Clean the exterior of the weld fume extraction to remove any dust, debris, or welding spatter.

Clean the interior components, such as the fan, motor, and airways, to ensure optimal performance.

For models with a collection drum or bin, empty it regularly and clean it to prevent the build-up of dust and metal particles.

Airflow Check of Welding Fume Extraction

Periodically check the airflow to ensure it meets the specifications provided by the manufacturer. Reduced airflow can indicate a clogged filter or other issues.

Motor and Fan Maintenance of Welding Fume Extraction

Check the motor and fan for any signs of wear or damage.

Ensure the fan is balanced and that there are no unusual noises during operation.

Lubricate moving parts as needed, following the manufacturer's guidelines.

Ductwork Inspection of Welding Fume Extraction

Inspect the ductwork for any kinks, damage, or loose connections that could impede airflow.

Clean the inside of the ductwork periodically to prevent the accumulation of fumes and particles.

Functional Testing of Welding Fume Extraction

Test the fume extractor welding regularly to ensure it starts up correctly and operates as intended.

Check the fume extractor's alarm systems and indicators to make sure they are functioning correctly.

Replacement Parts of Welding Fume Extraction

Keep a stock of replacement filters and other consumable parts to avoid downtime.

Replace any damaged or worn parts promptly.

Professional Maintenance of Welding Fume Extraction

Schedule regular maintenance with a professional service that specializes in fume extraction systems.

Follow the professional manufacturer's recommended service intervals. Power Space, 15 years industrial fume extractions supply, click there for experts suggestions!

Record Keeping of Welding Fume Extraction

Keep a maintenance log that records all inspections, cleanings, replacements, and any issues that arise. This log can help track the history of the machine and ensure that maintenance is performed on schedule.

By following these maintenance steps, you can keep your welding fume extractor operating effectively, reduce the risk of breakdowns, and provide a safer working environment for welders and other personnel. Always refer to the manufacturer’s manual for specific maintenance instructions and safety guidelines for your particular model of fume extractor.