News

Power Space tailor-made dust removal plan for you

How to Choose the Right Laser Fume Extractor

Laser fume extractors play a crucial role in industrial settings, particularly where laser cutting processes generate significant smoke and dust. Selecting a high-quality laser fume extractor is essential for maintaining a clean and safe working environment. In this article, we will explore the key aspects to consider when choosing the right laser fume extractor.

Understanding Laser Fume Extractors

Laser processes, while essential in various industrial applications, give rise to potentially harmful byproducts in the form of laser dust. These minuscule airborne particles can have serious health implications when inhaled. Common health hazards include respiratory distress, eye irritation, skin problems, and, in the long term, more severe conditions like lung diseases and cancer. Thus, it is imperative to mitigate the risks associated with laser dust exposure.

A laser fume extractor, also known as a laser cutting dust collector or laser smoke extractor, is a specialized filtration system designed to remove hazardous fumes, smoke, and particulates generated during laser cutting processes. It ensures that the air within the workspace remains clean and safe for workers.

Characteristics of a High-Quality Laser Fume Extractor

High Airflow: A top-tier laser fume extractor should feature a large airflow capacity to effectively capture and remove contaminants from the air.

Strong Suction Power: The extractor should possess powerful suction capabilities to efficiently pull in smoke and dust particles, preventing them from dispersing into the environment.

High Filtration Efficiency: A quality fume extractor is characterized by its ability to achieve a high purification rate, effectively filtering out harmful substances and ensuring clean air output.

Low Noise: Noise levels are a crucial consideration, especially in industrial settings. A premium fume extractor operates quietly, minimizing disruption to the work environment.

Automatic pluse clean system:Integral to the seamless operation of laser fume extraction is an automated pulse cleaning system, engineered for efficiency and efficacy. Comprising both online and offline automated cleaning modalities, this system boasts simplicity of operation sans intricate configurations. Leveraging specialized pulse jetting devices, dust adhered to the surface of filters undergoes facile removal, preserving filter integrity and elongating operational lifespan. This meticulous maintenance regimen ensures sustained filtration efficacy, facilitating a stable output of dust removal throughout operational cycles.

High performancefan design: Central to the prowess of laser cutting dust collector is the proprietary development of high-efficiency fans. Crafted from premium aluminum impellers and subjected to iterative testing and refinement, these fans exhibit a 15% increase in both air volume and pressure compared to conventional counterparts. This augmented suction capability excels in capturing smoke generated during laser cutting processes, bolstering overall air quality within industrial precincts.

Compacr and Streamlined Architecture: Rounding off the manifold advantages of laser cutting fume extractor is their ingeniously engineered form factor. Embracing a transverse filter cartridge and front-end purification chamber configuration, these fume extractors epitomize efficiency and space optimization. The synergy between purifier doors and casings yields a unified purification chamber unit, fostering unimpeded airflow pathways and a compact structural footprint. Occupying a mere 1.2-2 ㎡ of space, these purifiers offer plug-and-play functionality, coupled with automatic offline cleaning, rendering them eminently user-friendly. With a learning curve of mere minutes, these purifiers effortlessly tackle the scourge of laser cutting fume extraction.

How to Choose the Right Laser Fume Extrator

Understanding Laser Cutting Machine Models and Structures.

When selecting a laser fume extractor, it's essential to consider the specifications and structure of the laser cutting machine it will be used with. This includes understanding the laser cutting machine model, laser power, the position of the air intake, and other relevant details.

Understanding the Processing Environment.

Factors such as the types of materials being cut, the cutting gases used, typical cutting speeds, and the duration of daily machine operation all impact the selection of a suitable fume extractor. A thorough understanding of the processing environment is necessary to ensure optimal performance and compatibility.

Recommended High-Quality Laser Fume Extractors.

POWER SPACE is a reputable manufacturer with over 15 years of experience in producing laser fume extractors. Our products are known for their exceptional quality, high performance, and competitive pricing. If you require further details or assistance, please don't hesitate to contact us.

How to Install Laser Fume Extraction

Inspect the Unit: Before installation, please check the exterior, components, and electrical parts of the laser fume extractor. If there are any issues, contact us to ensure your service rights.

Connect the Hose or Ducts: Use either flexible hoses or rigid ductwork to connect the plasama fume extractor's dust interface to the laser cutting machine's fume outlet. Apply sealant to ensure an airtight seal and avoid increasing air resistance. We recommend using high-quality rigid ductwork or premium-grade flexible hoses with some stiffness to prevent collapse.

Electrical Installation: Following electrical usage standards, connect the power supply properly. Press the control panel switch to check if the fume extractor starts up normally. If it doesn't start, there may be a phase sequence issue with the power supply; in this case, switch the phase sequence and restart.

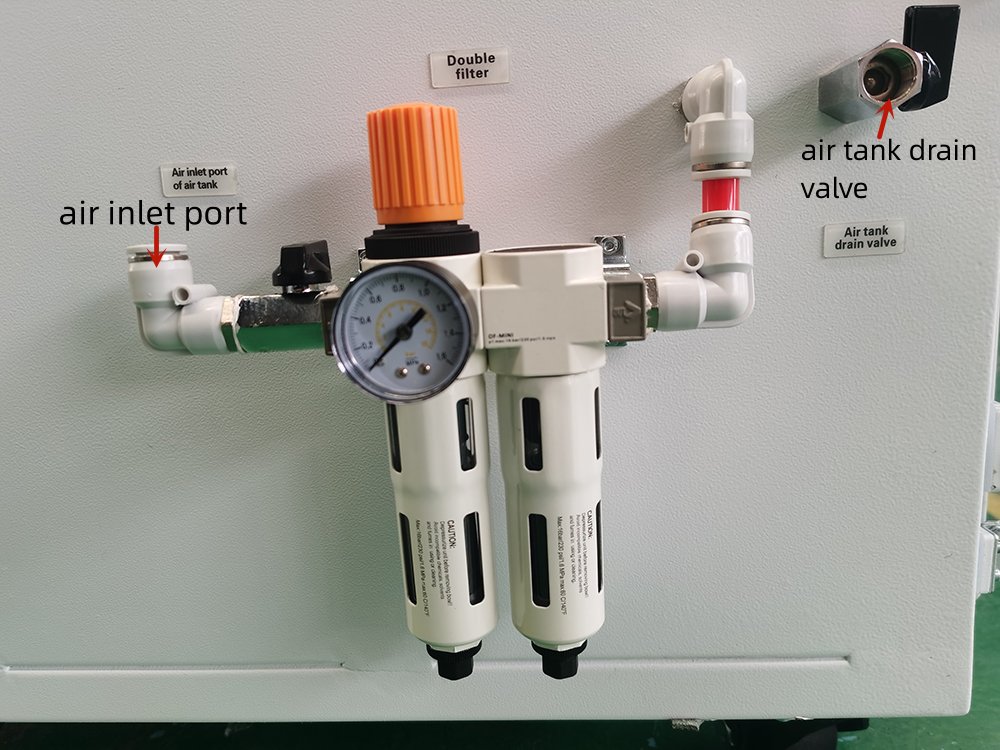

Connect Compressed Air: Using a 12mm air source hose, connect the compressed air supply (0.5-0.6Mpa) to the inlet of the fume extractor (as shown in the diagram) and ensure the adjacent drain valve is closed.

Conclusion

selecting the right laser fume extractor is crucial for maintaining a safe and healthy work environment in laser cutting facilities. By considering factors such as airflow capacity, suction power, filtration efficiency, machine compatibility, and the manufacturer's reputation, businesses can make informed decisions to ensure effective fume extraction and worker safety.