News

Power Space tailor-made dust removal plan for you

Q&A on Laser Fume Extractors

Laser dust collectors are effective tools in ensuring a safe working environment. But what equipment can use laser fume extractor? How to protect laser fume extractor? These Q&A can help you!

Q: Which Machines are Compatible with Laser Fume Extractors?

A: Laser cutting machines like plate-cutters and tube-cutters. Plasma cutting fume extractor removes the fumes produced in these processes (both larger and finer particles), and release purified air into the environment.

Q: What unit filters industrial fumes in this equipment?

A: Filter cartridges. Typically, they last 3600 to 6000 hours, but with Ahlstrom materials from Power Space, they last up to 8000 hours! And you don't worry about replacement process because only a single fixed screw.

Q: Can this Equipment Eliminate Odors?

A: No. Plasma cutting fume extraction is designed to purify smoke and dust particles, not gas molecules, including odors.

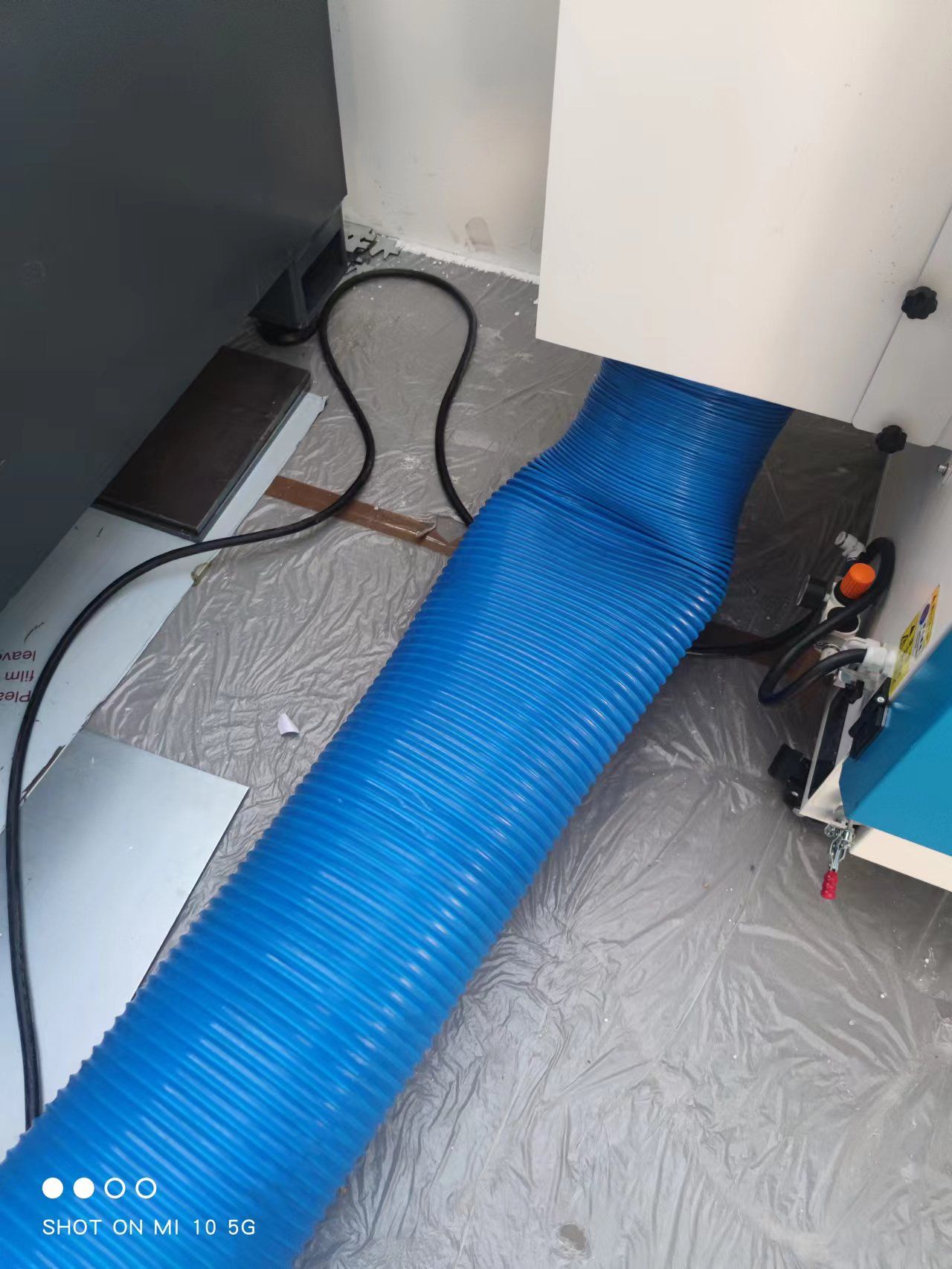

Q: Why the fume extractor's performance seem less than optimal?

A: You can check the connection pipeline between the laser cutting machine and the extractor firstly. The ideal connection uses rigid materials like galvanized iron spiral ducts. While cost-saving measures might involve slightly rigid PU hoses, it's crucial to avoid excessive bends in the pipeline, as significant bends can severely impact dust extraction efficiency.

In conclusion, laser fume extractors are essential for a clean and safe laser cutting environment. Power Space commitment to quality materials and engineering enhances the effectiveness of laser fume extractors in managing industrial fumes, making them a reliable choice for businesses prioritizing air quality.