News

Power Space tailor-made dust removal plan for you

What is the mobile industrial welding fume extractor suitable for?

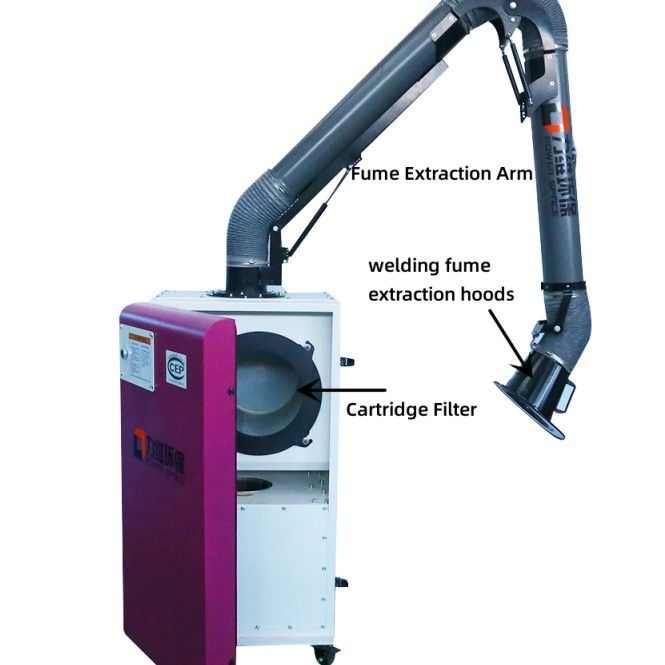

In the realm of industrial air quality management, the significance of effective welding fume control cannot be overstated. Addressing the unique challenges posed by various welding scenarios, the mobile industrial welding fume extractor emerges as a versatile solution. This article delves into the specific work conditions where the welding fume extractor proves to be exceptionally applicable.

What is the mobile industrial welding fume extractor suitable for?

When dealing with the welding of small workpieces, the precision required demands a specialized approach to fume extraction. The welding fume extractor excels in capturing and filtering out the fumes generated during the welding process on diminutive workpieces, ensuring a clean and safe working environment.

In scenarios where welding is confined to specific workstations, a welding dust collector becomes indispensable. Its ability to extract and purify the air in a localized manner makes it ideal for fixed point welding. This targeted approach not only enhances the efficiency of fume extraction but also contributes to a healthier work environment for the personnel involved.

Metal cutting operations often result in the generation of fine dust particles laden with sparks. The welding fume eater, equipped with advanced filtration technology, proves highly effective in capturing these minute particles, ensuring that the workplace remains free from potential hazards associated with combustible dust and sparks.

Whether it's tin soldering, manual welding, or manual arc welding, the welding fume extractor exhibits remarkable adaptability. Its design is tailored to accommodate a spectrum of welding processes, making it a valuable asset in workshops where diverse welding techniques are employed. The welding fume extractor ensures that regardless of the welding method, the air quality remains optimal.

The Facts to select fume extraction

Selecting the right fume extraction system is crucial for maintaining a safe and healthy work environment, particularly in industries where hazardous fumes, dust, and gases are produced. Calculate the volume of air that needs to be moved to effectively capture and control the fumes. This is typically measured in cubic feet per minute (CFM) or liters per second (L/s); The system should be able to capture fumes at their source to prevent them from spreading throughout the workspace. The design of hoods, ductwork, and extraction arms is critical for efficient capture; Consider the energy consumption of the extraction system. More efficient systems can reduce operational costs.

When selecting a fume extraction system, it is often beneficial to consult with professionals who can assess your specific needs and recommend the most appropriate solution. Additionally, involving employees in the selection process can help ensure that the system meets their needs and is user-friendly.

The Cost-benefit Analysis of a Welding Fume Extraction

Calculate the total cost of purchasing, installing, and maintaining the welding fume extraction system. This includes equipment costs, transportation fees, installation costs, and potential training expenses. Consider the energy consumption, replacement of consumables (such as filters), regular maintenance, and potential repair costs required for daily operation. Assess the potential reduction in health risks and related medical expenses for workers due to decreased exposure to harmful fumes. Moreover, improving the work environment may increase employee productivity and morale. Check whether the system meets local regulations and standards to avoid fines or other legal issues resulting from non-compliance. Investigate whether there is evidence to suggest that a cleaner work environment can increase worker efficiency and product quality. When conducting a cost-benefit analysis, financial indicators such as Net Present Value (NPV) and Internal Rate of Return (IRR) can be used to quantify the return on investment. At the same time, non-financial factors, such as social and environmental benefits, should also be considered.

Conclusion

The welding fume extractor, acting as a welding dust collector and weld fume eater, is a pivotal tool in the arsenal of industrial air quality management. Its application spans a spectrum of welding scenarios, from the meticulous welding of small workpieces to the precision required in fixed point welding. Moreover, its capability to handle metal cutting dust, enriched with sparks, adds another layer of safety to the workplace. In essence, investing in a mobile industrial welding fume extractor is a proactive measure towards fostering a healthier and safer working environment.