News

Power Space tailor-made dust removal plan for you

Air-Clean Tower: Revolutionizing Fume Extraction in Complex Welding Shops

Introduction

Large welding facilities face unique challenges in fume management that traditional extraction systems cannot adequately address. This case study explores how an innovative air-clean tower solution transformed a complex welding shop's air quality using advanced fume extraction clean tower technology. The implemented fume extraction system demonstrates how modern approaches can overcome even the most challenging industrial environments.

Case Study: Complex Welding Facility Overview

Facility Specifications

Total area: 12,000 square feet welding shop

Layout complexity: Multiple work zones with varying ceiling heights

Welding types: MIG, TIG, and stick welding operations

Workstation arrangement: 40+ fixed stations with mobile operations

Challenge: Traditional ducting impossible due to overhead cranes and infrastructure

Air Quality Challenges

Widespread contamination: Fumes spread throughout facility

Worker health concerns: Multiple respiratory complaints

Regulatory compliance: OSHA violations documented

Production impacts: Frequent work stoppages for air quality issues

Traditional System Limitations

Failed Approaches

Centralized Duct Systems

Installation interfered with crane operations

Insufficient coverage for facility size

High energy consumption

Individual Station Units

Inconsistent air quality between stations

Maintenance management challenges

Higher overall operating costs

General Ventilation

Ineffective for fume containment

High energy costs for minimal benefit

Unable to meet OSHA requirements

Innovative Solution: Air-Clean Tower Deployment

Design Philosophy

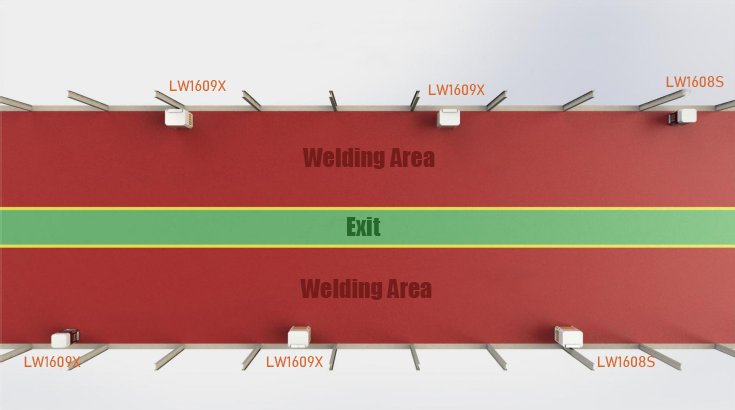

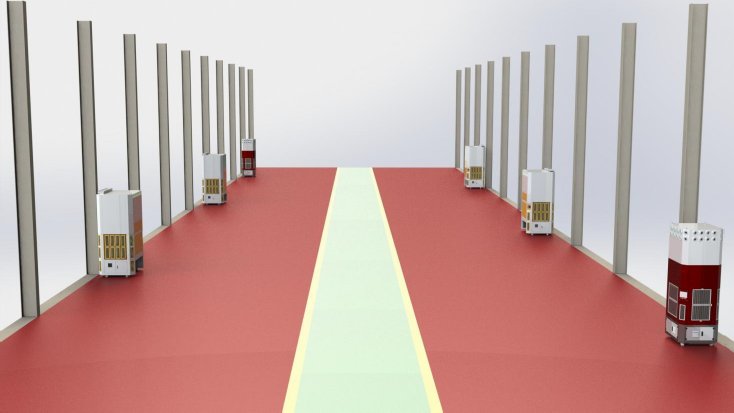

The solution combined fixed air-clean tower units with mobile collectors:

Strategic placement: Based on computational fluid dynamics analysis

Zoned approach: Different models for different area requirements

Mobile support: Flexible units for variable work locations

Technical Implementation

6 self-circulating units deployed throughout facility

4 × LW-E-1609X units: High-capacity coverage for main welding areas

2 × LW-C-1608S units: Specialized units for finishing areas

Mobile units: LW-C-M1201 for flexible support where needed

Equipment Configuration & Placement

Fixed Tower Placement Strategy

| Location | Model | Coverage Area | Special Features |

|---|---|---|---|

| Main welding bay | LW-E-1609X | 3,000 ft² | High-capacity filtration |

| Secondary bay | LW-E-1609X | 2,500 ft² | Enhanced spark protection |

| Finishing area | LW-C-1608S | 1,800 ft² | Fine particulate control |

| Quality control | LW-C-1608S | 1,200 ft² | Ultra-clean air output |

Mobile Unit Deployment

3 × LW-C-M1201 mobile units

Flexible positioning: Follows project requirements

Quick connectivity: Instant operation where needed

Backup capability: Supports fixed units during maintenance

Performance Results & Benefits

Air Quality Improvements

95% reduction in airborne particulates

OSHA compliance achieved within 30 days

Worker satisfaction dramatically improved

No more production delays due to air quality

Operational Benefits

40% reduction in energy costs vs. traditional system

Minimal maintenance requirements

No interference with existing infrastructure

Scalable solution for future expansion

Financial Impact

Return on investment: 14 months

Maintenance cost reduction: 60%

Insurance premium reduction: 25%

Productivity improvement: 18%

The Future: LW16 Series Fume Extraction Tower

Advanced Technology Features

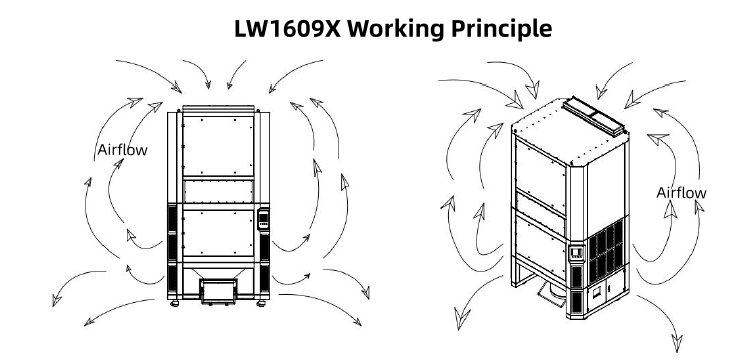

Power Space's latest LW16 series fume extraction tower incorporates:

Self-developed control system: Intelligent airflow management

Dual-mode operation: Combination units create effective air circulation patterns

Enhanced filtration: 99.97% efficiency at 0.3 microns

Smart monitoring: Real-time performance optimization

Key Advantages

30% faster contamination removal than previous models

20% energy reduction through smart cycling

Remote monitoring and predictive maintenance

Adaptive operation based on real-time air quality

Expert Consultation Available: Click here to connect with our engineering team for a custom facility assessment and solution design.

Conclusion

This case study demonstrates how modern air-clean tower technology can solve even the most challenging welding fume extraction problems. The implemented fume extraction clean tower system provided comprehensive coverage without disrupting existing operations, while the fume extraction system overall delivered exceptional air quality improvements and operational benefits. For facilities facing similar challenges, the LW16 series fume extraction tower represents the next evolution in industrial air cleaning technology.

Next Step: Contact Power Space for a comprehensive facility assessment and customized fume extraction system design tailored to your specific requirements.