Product Show

LW series high qiality fume extractors are designed for industrial fume extraction.

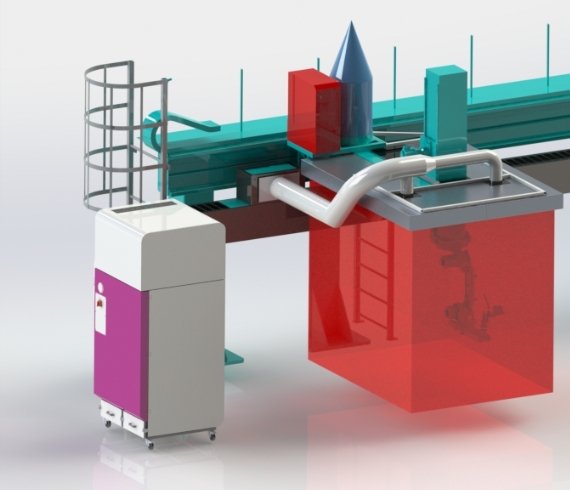

Plasma Cutting Fume Extractor

LW12 Series Centralized Plasma Dust Collection System is engineered specifically for high-intensity metal processing. Whether you are operating a single unit or a full-scale production line, our Automated Plasma Cutting Ventilation technology integrates seamlessly with your CNC Plasma Table Smoke Extraction needs.

Designed for durability and efficiency, this system utilizes a Multi-Stage Filtration System to capture 99.9% of airborne particulates, ensuring your facility remains an OSHA Compliant Metal Fume Extraction zone.

- LW-C-1204-055

- LW-C-1206-075

- LW-C-1209-110

Product parameter

Model | LW-C-1204-055 | LW-C-1206-075 | LW-C-1209-110 |

| Motor Power | 5.5kW | 7.5kW | 11kW |

| Voltage | 3*380V/50Hz | ||

Dimension (L*W*H) | 1935*1170*1460mm | 1120*1310*2355mm | 1570*1370*2560mm |

| Noise | ≤78dB | ||

Stop letting smoke and noise affect your productivity! Contact us now to Request a Quote / Get Price Table.

Product Details

Application of Plasma Cutting Fume Extractor

1. Material Focus: Ideal for dust management during the cutting of carbon steel, stainless steel and alloyed metals.

2. Industry Use: Widely applied in sheet metal fabrication, automotive parts manufacturing, signage cuuting, and cabinet production.

3. Equipment Pairing: Large-scale CNC plasma and laser cutting tables.

Advantages of Plasma Cutting Fume Extractor

1. Direct factory supply ensures the more competitive price with a superior ROI.

2. External spark trap design intercepts high-temperature sparks, eliminating fire risks and extending filter life.

3. Advanced noise redction technology ensures a decibel level far lower than industry standards.

4. Heavy-duty steel construction and premium guarantee 24/7 stable operation in harsh enviroments.

User Evaluation

-

Gregory Scott (Plant Manager)

Managing a 10x40 foot cutting area requires a serious CNC Plasma Table Smoke Extraction strategy. We integrated this sectional zoning system, and it's incredibly efficient. It only activates the suction in the specific zone where the torch is currently cutting, which maximizes static pressure and saves on energy costs. The shop remains clear of that heavy metallic plasma smell even during 12-hour shifts of high-definition cutting.

-

Steven Wright (Procurement Manager)

This system's heavy-duty spark arrestor was the deciding factor. It's a robust piece of equipment that helped us meet our local EPA requirements for air discharge.

-

Jason Miller (Engineer)

I've spent 20 years behind a torch, and this is the best Plasma Cutting Fume Extractor I've worked with. The pulse-jet cleaning on the filters is surprisingly quiet, which makes for a much better working environment.

Inquire Now

If you have any questions or needs about the product, please fill in the following form and we will contact you as soon as possible.