Cases

Effective solution for industrial fume extraction system

| Customer Condition | Welding zong+Air Gouging Zone |

| Product | LW1112 |

In the heavy manufacturing sector, air quality compliance is a critical operational standard. We recently partnered with a client facing severe environmental challenges in their production facility. This case study details how we engineered a centralized fume extraction system to handle the complex mix of welding fumes and heavy particulate matter from air gouging.

Project Background: The Need for a High-Performance Welding Shop Fume Extractor

The client's facility comprised a mixed-use workshop with two distinct operational zones that generated significant pollution:

Welding Zone: 10 active workstations producing continuous fine welding fumes.

Air Gouging Zone: 1 specialized station. Carbon arc gouging generates heavier smoke and dust compared to standard welding, requiring a more robust capture method.

The primary challenge was to install a welding shop fume extractor that could handle these different pollutants simultaneously while adhering to strict national regulations. The client needed a solution that was safe, reliable, and energy-efficient without causing secondary pollution.

Our Solution: A Centralized Fume Extraction System Design

Based on our "Capture + Transport + Central Treatment" methodology, we designed a bespoke fume extraction system. The system ensures that fumes are captured at the source before they can contaminate the workshop air.

(Fume removal process)

To address the specific physical constraints of the site, we customized the capture devices for each zone:

1. Welding Zone: 7-Meter Extension for Flexibility

For the 10 welding stations, standard arms were insufficient for the large workpieces. We installed specialized 7-meter extension arms (comprising a 4-meter extension rod + a 3-meter flexible suction arm).

Advantage: This setup allows the welding shop fume extractor to cover a wide radius. Welders can reach any point of a large workpiece without frequently moving the base, ensuring continuous fume capture.

2. Air Gouging Zone: Rotating Hood for Crane Access

The air gouging station presented a logistical challenge: heavy workpieces needed to be hoisted by a crane. A fixed hood would block the crane's path.

Innovation: We designed a rotating top suction hood equipped with soft curtains.

Workflow: During lifting operations, the hood rotates away to clear the space. Once the workpiece is positioned, the hood rotates back over the station to capture dust. This smart design integrates the fume extraction system seamlessly into the client's logistics flow.

(fume extraction hood with soft curtains)

Technical Spotlight: 99.99% Filtration Efficiency

The core of any fume extraction system is the filtration unit. For this project, we utilized imported flame-retardant filter materials to ensure safety against hot sparks.

Filtration Efficiency: The system achieves an impressive ≥99.99% efficiency for particles ≥0.1μm.

Advanced Pleating Technology: Our proprietary pleating process increases the filtration area, significantly reducing wind resistance.

Longer Lifespan: Combined with an automatic pulse-jet cleaning system, the filters maintain stable airflow and offer a service life 2-3 times longer than traditional materials. This reduces the maintenance cost of the welding shop fume extractor significantly.

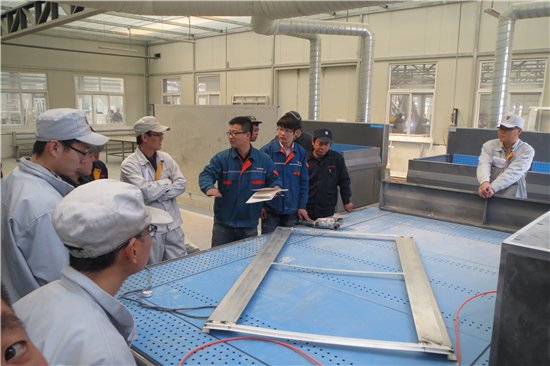

Implementation & Technical Training

We believe a fume extraction system is only effective if the operators know how to use it. Upon final acceptance at the user's factory, our team conducted comprehensive on-site training for 3-4 of the client's technical staff.

The training covered:

System Principles: Understanding the mechanics of the welding shop fume extractor.

Operation: Standard procedures for the rotating hoods and extension arms.

Maintenance: Routine checks to ensure the system remains energy-efficient and reliable.

(Technical Trainning)

Conclusion

This project highlights our ability to deliver a tailored fume extraction system that solves specific site challenges—from crane interference to heavy dust loads. By combining flexible hardware with high-efficiency filtration, we provided a clean, compliant, and safe environment for the client.

If you are looking for a professional welding shop fume extractor solution, contact us today to discuss your facility's needs.