News

Power Space tailor-made dust removal plan for you

Laser Cutter Fume Extractors for a Safe Workshop

Many business owners invest heavily in state-of-the-art laser cutters but consider the accompanying air filtration system an optional extra. This is a dangerous and costly mistake. The reality is, the smoke generated from laser cutting is a toxic cocktail of particles and gases that poses a significant threat to your employees' health, the longevity of your expensive equipment, and your company's ability to meet increasingly strict environmental regulations.

This article will shed light on the unseen dangers of laser cutting and explain why a professional-grade laser cutter fume extractor is not just an accessory, but a fundamental component of a safe, compliant, and profitable modern workshop.

Deconstructing the Hazards of Laser Cutting Fumes

When a high-powered laser beam vaporizes material, it doesn't simply disappear. It transforms into a cloud of smoke and dust, technically known as a plume. This plume is a complex mixture of very fine particulate matter (often smaller than 2.5 micrometers, or PM2.5), aerosols, and potentially toxic gases. The exact composition depends on the material being cut, but it often contains metallic oxides, carbon monoxide, and other harmful compounds.

These particles are so small that they can bypass the body's natural defenses and embed deep within the lungs. For your workforce, prolonged exposure is not a trivial matter. Inhaling these fumes day after day can lead to a range of severe occupational diseases, including:

Pneumoconiosis: A debilitating and irreversible lung disease caused by the accumulation of dust in the lungs, leading to shortness of breath, chronic coughing, and permanent lung damage.

Respiratory Infections: The constant irritation of the respiratory tract makes workers more susceptible to bronchitis and other infections.

Eye and Skin Damage: The fumes can cause significant irritation to the eyes and skin, creating an uncomfortable and unsafe working environment.

Protecting your employees is not just a moral and legal obligation; it's good business. A workshop with poor air quality will inevitably suffer from lower productivity, higher rates of absenteeism, and difficulty retaining skilled staff. Investing in an effective laser fume extraction system is a direct investment in the health and well-being of your most valuable asset: your people.

Protecting Your Investment: How Laser Fumes Silently Damage Your Equipment

Your laser cutter is a precision instrument and a significant capital investment. It's designed to operate with incredible accuracy, but its performance is highly dependent on the condition of its sensitive components, particularly its optical lenses and mirrors. This is where the insidious nature of laser cutting fumes causes the most damage.

The fine dust particles generated during cutting don't just float away. They settle on every surface, including the delicate lens of the laser head. This contamination has several detrimental effects:

Reduced Cutting Power: A layer of dust on the lens will absorb and scatter the laser beam's energy, reducing its cutting efficiency. This forces you to run the machine at higher power settings, consuming more energy and putting extra strain on the laser source.

Poor Quality Finishes: A compromised beam results in rougher cuts, incomplete penetration, and a higher rate of scrapped parts, wasting both time and materials.

Catastrophic Failure: Over time, the heat absorbed by the contaminated lens can cause it to crack or even shatter. Replacing a high-quality optical lens is an expensive and time-consuming repair that brings your entire production to a halt.

By failing to install a proper dust collector for your laser cutter, you are allowing your investment to be slowly degraded from the inside out. The cost of a fume extraction system is minuscule compared to the potential cost of major equipment repairs and lost production time.

Choosing the Right Laser Cutter Fume Extractor for Your Needs

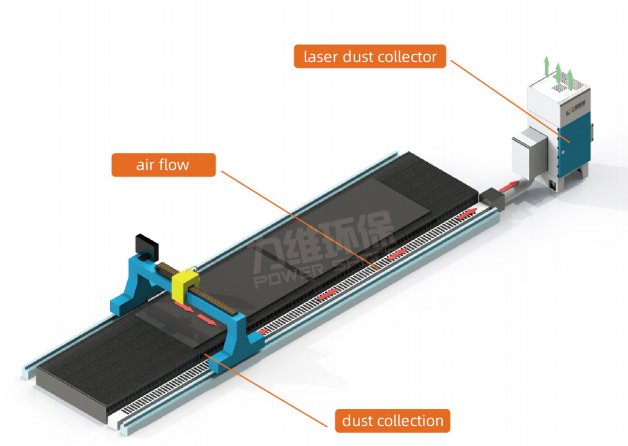

Fortunately, solving the problem of laser fume pollution is straightforward with the right equipment. A dedicated laser cutter fume extractor is specifically designed to capture these harmful particles and gases at the source, before they can escape into the workshop environment.

When selecting a system, look for a solution that is not just effective, but also practical for your workspace. Modern units, like those developed by specialists such as Power Space Environmental Protection, are engineered to be highly efficient and user-friendly. Key features to consider include:

High-Efficiency Filtration: A multi-stage filtration process is crucial. This typically includes a pre-filter for larger particles, a HEPA fume extractor filter to capture the finest sub-micron dust, and an activated carbon filter to adsorb harmful gases and odors.

Powerful Suction: The system must have sufficient airflow and suction power to create a negative pressure zone around the cutting area, ensuring all fumes are drawn directly into the unit.

Compact and Convenient: In a busy workshop, floor space is at a premium. A well-designed fume extractor should have a compact structure and a small footprint, making it easy to install and integrate into your workflow.

Quiet Operation: A noisy machine adds to workplace stress. Look for a unit designed for low-noise operation to maintain a more pleasant and productive environment.

Conclusion: An Essential Investment for a Modern, Responsible, and Profitable Workshop

The evidence is clear: the plume of smoke from your laser cutter is far from harmless. It is a direct threat to the health of your employees, the performance of your machinery, and the legal standing of your business.

Thinking of a laser cutter fume extractor as an optional expense is a perspective of the past. In the modern industrial landscape, it is a core component of a successful operation. It is an investment in safety, efficiency, and sustainability. By ensuring clean air in your workshop, you are not only protecting your people and your equipment; you are future-proofing your business, safeguarding your reputation, and building a foundation for long-term growth and success.