News

Power Space tailor-made dust removal plan for you

What is the effect of laser bed on the connection pipe of laser cutting fume extractor

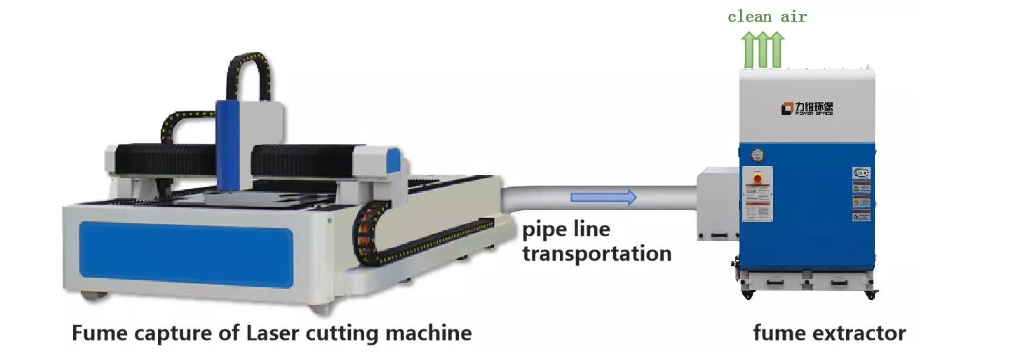

With the development of laser cutting machines gradually replacing traditional mechanical processes, they have found extensive applications in the industrial field. However, the associated issue of smoke and dust particles demands significant attention. These minute particles are easily inhaled by humans, posing substantial health risks to operators. Prolonged exposure in such an environment can lead to a range of occupational illnesses. To address these concerns, specialized laser cutting fume extractors have emerged on the market. Today, we will discuss the impact of connecting pipes between the laser bed and the laser fume extraction.

The connection of dust removal pipes between the laser bed and the laser dust collector is closely tied to the pressure loss within the pipes. If the pipes are excessively long, narrow, have multiple bends, or possess rough inner surfaces, it can lead to reduced pressure and subsequently affect the dust removal efficiency. In terms of pipe connections, it's advisable to keep the pipes relatively short, generally around 4 meters, and not exceeding 6 meters. Whenever possible, opt for rigid spiral ducts, which feature smooth inner walls and lower air resistance. For three-way connections, it's recommended to use Y-type tees, with the tee's interface being one size larger for optimal performance. If flexible hoses are used, select hoses with higher hardness and avoid sharp bends to prevent collapsing during suction.