News

Power Space tailor-made dust removal plan for you

Oil Mist Collector: Essential Protection for CNC

In the world of CNC machining, precision and efficiency are paramount. However, the use of metal cutting fluids to lubricate and cool the cutting tools during operations inevitably generates oil mist. This byproduct not only poses significant health risks to workers but also threatens the performance and longevity of the machines. That's where the oil mist collector comes into play. An oil mist collector for CNC machines is a crucial piece of equipment that helps mitigate these issues, ensuring a safer and more productive working environment.

Understanding the Dangers of Oil Mist in the Workplace

Oil mist, created when metalworking fluids are sprayed onto cutting tools and workpieces, can have detrimental effects on both human health and machinery. When inhaled, oil mist particles can irritate the respiratory system, leading to conditions such as asthma, bronchitis, and other respiratory ailments. Moreover, the accumulation of oil mist on machine surfaces can cause slipping hazards, increasing the risk of accidents. For CNC machines, oil mist can clog filters, contaminate electrical components, and reduce the overall efficiency of the equipment. Therefore, it is imperative for CNC machine shops to implement effective oil mist collection systems to safeguard their workers and machinery.

How Oil Mist Collectors Work

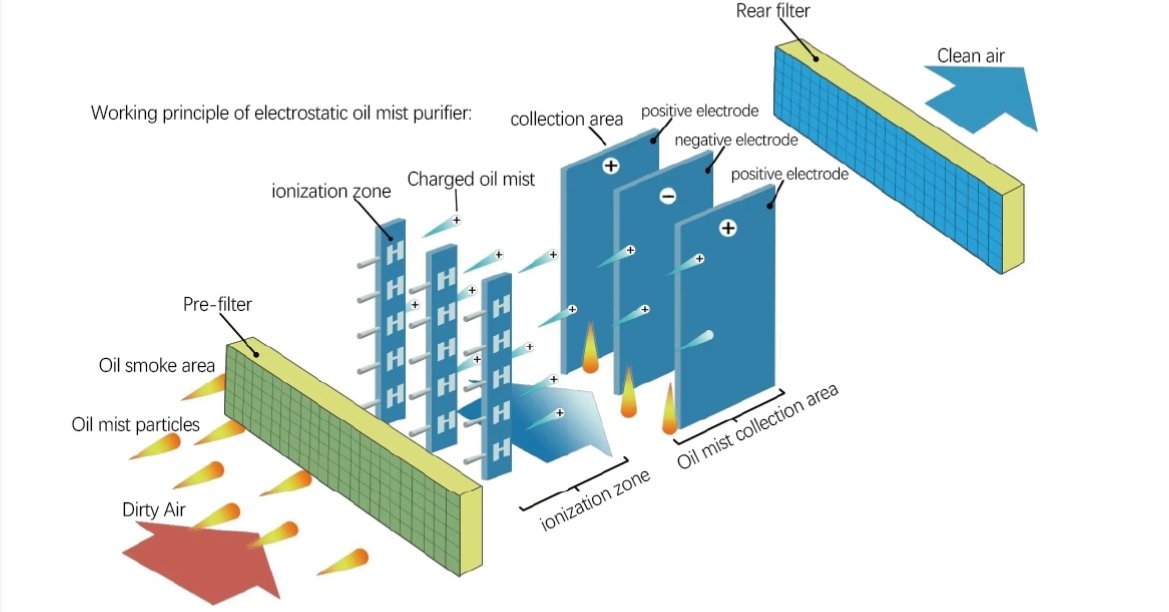

Oil mist collectors are specifically designed to capture and remove oil mist from the air. They typically utilize a combination of filtration methods to achieve this. The first stage often involves a pre-filter that captures larger oil droplets and debris. This helps to prolong the life of the subsequent filters. The main filtration stage usually employs high-efficiency filters, such as HEPA filters or pleated filters, which can capture smaller oil mist particles down to a size of 0.3 microns or even smaller. Some advanced oil mist collectors also incorporate electrostatic precipitators, which use an electrical charge to attract and trap oil mist particles. By effectively removing oil mist from the air, these collectors ensure that the air in the workshop remains clean and breathable, protecting both workers and machines from potential harm.

Key Benefits of Oil Mist Collector System

Precision CNC Swiss machines particularly benefit from oil mist control:

Component Protection

Prevents buildup on guideways

Reduces electrical cabinet contamination

Extends bearing life

Workplace Safety

Meets OSHA permissible exposure limits

Reduces slippery floor hazards

Improves visibility

Cost Savings

90% fluid recovery rate

Reduced machine downtime

Lower fluid consumption

Regulatory Compliance

Satisfies local air quality regulations

Documentation for inspections

Worker protection standards

Select Oil Mist Collector for CNC

When selecting an oil mist collector for CNC Swiss-type applications, it's critical to provide your manufacturer with detailed working conditions to ensure optimal performance. Key factors to specify include:

1. Processing Methods

Different machining operations generate varying oil mist characteristics:

Turning: Produces fine, airborne mist (1–5µm)

Milling: Generates larger droplets mixed with particulates

Drilling: High-pressure coolant creates dense mist

Grinding: Oil mist combined with fine abrasive particles

2. Processing Chamber Details

Provide these machine specifications:

Dimensions (L×W×H) to calculate required airflow

Cooling method (flood coolant, MQL, or high-pressure jets)

Dust exhaust port location (top/side/rear) for proper ducting

3. Workpiece & Production Data

Processing time per part (minutes/hours)

Daily working hours (8hr/24hr shifts)

Batch size (small/large volume)

4. Oil Mist Properties

Critical for filter selection:

Type: Mineral, synthetic, or semi-synthetic fluid

Temperature: Ambient vs. heated mist (>40°C requires special materials)

Concentration (mg/m³): Light (<5), Moderate (5–20), Heavy (>20)

Particle size distribution: 0.3–5µm (HEPA needed for sub-micron)

Conclusion

Investing in a proper oil mist collector system delivers measurable benefits for CNC Swiss-type lathe operations. The right oil mist collector for CNC applications reduces workplace contamination, extends machine tool life, and helps maintain regulatory compliance. By selecting equipment matched to your specific machining environment and following proper installation/maintenance practices, manufacturers can achieve cleaner, safer, and more productive operations. In precision machining environments, effective oil mist control isn't optional—it's an essential component of sustainable manufacturing.