News

Power Space tailor-made dust removal plan for you

The Ultimate Guide to On-Torch Extraction Systems

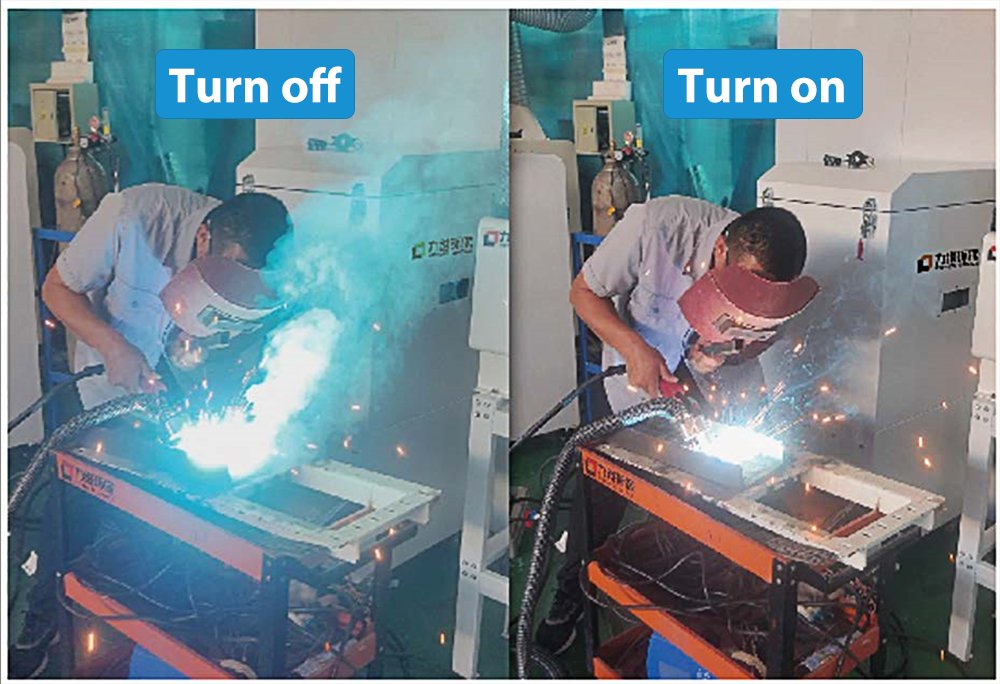

MIG welding is a cornerstone of modern metal fabrication, prized for its speed, versatility, and ease of use. However, it generates significant amounts of hazardous welding fumes at the source—directly in the welder's breathing zone. Traditional fume extraction methods, like overhead hoods, often struggle to capture these toxins effectively before the welder inhales them.

This is where on-torch fume extraction (also known as source capture or integrated extraction) becomes a game-changer. This guide will delve into how this technology works, its undeniable advantages, and what you need to know to implement it successfully.

What is On-Torch Fume Extraction?

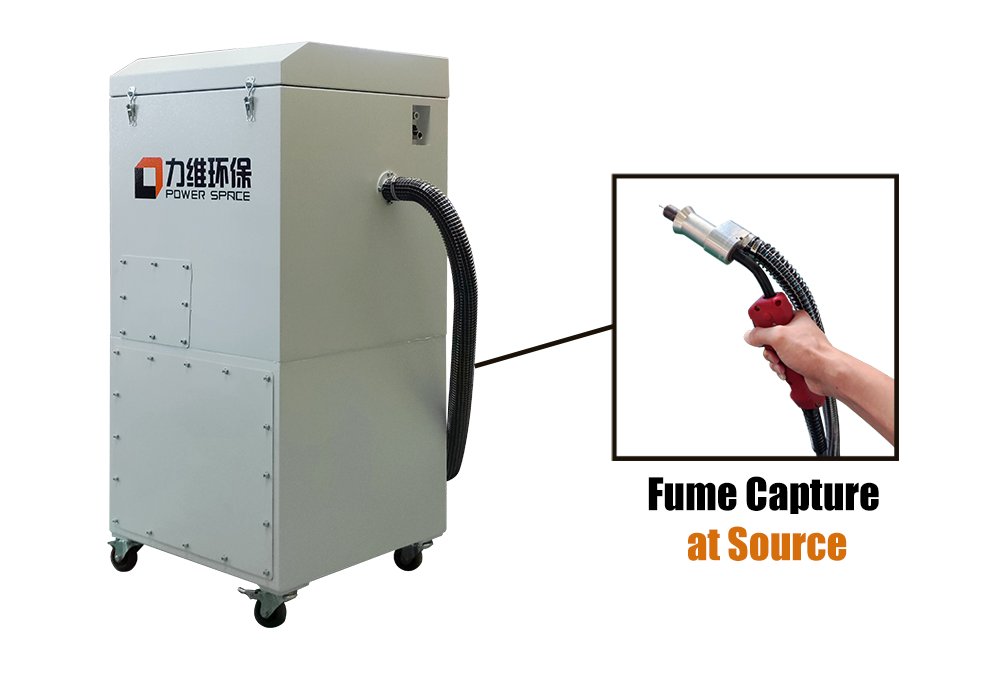

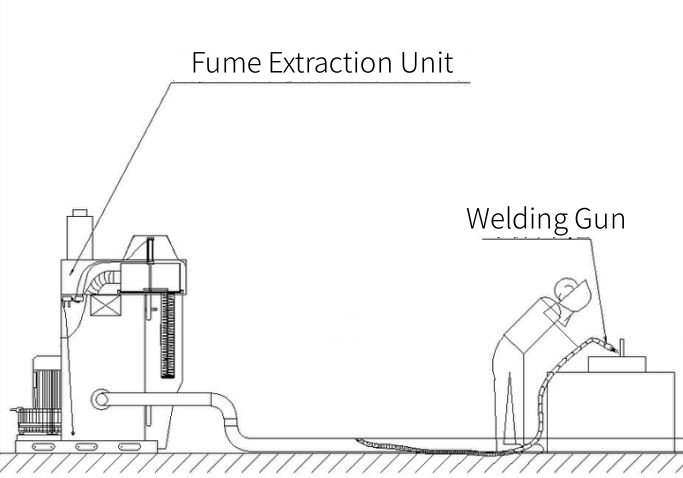

On-torch fume extraction integrates a fume capture device directly onto the MIG welding gun. Instead of waiting for smoke to fill the air, a vacuum system built into the machine pulls the fumes directly through the extraction gun and into a filter, capturing over 90% of contaminants at the source, before they can reach the welder's lungs.

Key Benefits of Integrating Extraction with Your MIG Gun

Unmatched Operator Health & Safety: This is the primary benefit. By capturing fumes at the arc, it drastically reduces the welder's exposure to harmful metals like hexavalent chromium and manganese, helping you comply with stringent OSHA and workplace safety regulations.

Increased Productivity: Welders no longer need to constantly reposition an external extraction arm. They have complete freedom of movement, leading to less interruption and more arc-on time. The workspace also remains clearer without large, obstructive hoods.

Cost-Effectiveness: While the initial investment may be higher, on-torch extraction is more efficient. It requires less overall energy to capture fumes at the source than a large ambient system needs to clean an entire shop's air. It also reduces the need for extensive ducting.

A Cleaner Workshop: By preventing smoke from dispersing, you keep not only the air cleaner but also your entire workspace. This leads to better visibility of the weld puddle, higher quality work, and reduced cleanup time.

Choosing the Right On-Torch Extraction System

Not all extraction guns are created equal. Consider these factors:

Suction Power & Airflow: Measured in cubic feet per minute (CFM), this determines the system's ability to pull in fumes effectively. Ensure the extractor unit paired with the gun has sufficient power.

Gun Ergonomics & Weight: A well-balanced gun is crucial to prevent welder fatigue. Modern extraction guns are designed to be only marginally heavier than standard MIG guns.

Filtration Quality: The central filter unit should feature a high-efficiency primary filter and a HEPA filter to capture ultra-fine particles, protecting both the welder and the vacuum motor.

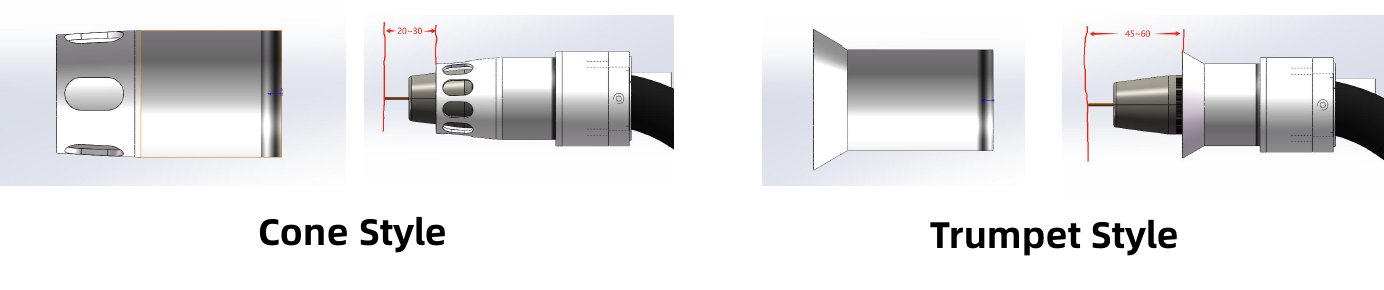

Attachment Nozzles: The right nozzle is critical for optimal capture. Common types include:

Cone Style Nozzles: Ideal for general-purpose MIG welding, offering a good balance of visibility and capture efficiency.

Trumpet Style Nozzles: Better for applications where more gas coverage is needed or for capturing fumes from thicker materials.

*Pro Tip: The distance between the nozzle and the welding arc is critical. For example, a Cone Style nozzle typically performs best at around 20mm, while a Trumpet Style may require 45mm. Always refer to the manufacturer's guidelines and be prepared to fine-tune based on your specific application.

Best Practices for Optimal Performance

To get the most out of your on-torch extraction system:

Maintain the Correct Distance: Keep the recommended distance between the extraction nozzle and the arc. Too far, and you lose capture efficiency; too close, and it can interfere with gas coverage and the weld.

Perform Regular Maintenance: Empty the collection bin regularly and check/clean filters as instructed by the manufacturer. A clogged filter drastically reduces performance.

Train Your Welders: Ensure operators understand how to use the equipment correctly and why it’s important. Their feedback is invaluable for troubleshooting.

Is On-Torch Extraction Right for Your Shop?

On-torch fume extraction is ideal for workshops where:

MIG welding is the primary process.

Jobs involve a variety of positions (overhead, vertical, etc.) where overhead hoods are impractical.

There is a high priority on operator health and regulatory compliance.

Management seeks to improve long-term productivity and efficiency.

Conclusion

Investing in an on-torch fume extraction system like those offered by Driclone is not just a purchase—it's an investment in your most valuable asset: your welders' health. It simultaneously enhances productivity, maintains a cleaner facility, and ensures regulatory compliance.

Ready to Breathe Easier?

Explore Power Space range of high-performance MIG welding fume extraction solutions and find the perfect system for your needs. Contact Our Experts Today for a Free Consultation!