News

Power Space tailor-made dust removal plan for you

Laser Smoke Collector: The Guide to Clean and Compliant Laser Cutting

Laser cutting generates hazardous smoke and particulate matter that poses serious health and environmental risks. Without a proper laser smoke collector, workshops can face regulatory fines, equipment damage, and worker health issues. This guide explains how to select the right laser cut smoke collector system and avoid common mistakes that compromise air quality and compliance.

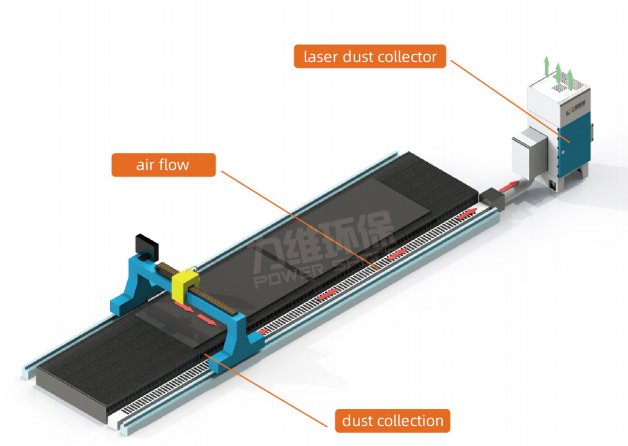

(Laser Dust Collector in Laser Machine)

The Critical Need for Laser Cutting Dust Control

Health and Regulatory Risks

Laser cutting without adequate filtration creates:

Airborne carcinogens: Benzene, formaldehyde, and metal oxides

Fine particulate matter: PM2.5 and sub-micron particles penetrate deep into lungs

Regulatory violations: OSHA PEL (Permissible Exposure Limits) and EPA standards

Without proper extraction, workshop particle concentrations can exceed legal limits by 10-20 times, resulting in:

Heavy fines from environmental agencies

Worker health complaints and lawsuits

Insurance premium increases

Equipment warranty voids

Key Technical Specifications for Effective Extraction

1. Machine Interface Design

Critical factors:

Hood size and placement: Must match laser cutting bed openings

Valve sealing: Prevents smoke leakage during cutting

Air velocity: Minimum 15-20 m/s at capture points

2. Machine Enclosure Considerations

Zoned compartmentalization: Contains smoke in cutting area

Sealing quality: Prevents smoke escape through gaps

Access design: Maintains sealing while allowing material loading

Common Laser Smoke Collection Mistakes

1. Using Inadequate Extraction Methods

Wrong approaches:

❌ Standard industrial fans (just spread contaminants)

❌ Basic shop vacuums (clog immediately)

❌ Direct exterior venting (environmental violation)

2. Mismatched Equipment Specifications

Typical problems:

Undersized airflow for material thickness

Wrong filter type for specific materials

Incompatible connection systems

Consequences:

Reduced cutting quality due to smoke interference

Frequent system shutdowns for cleaning

Premature filter failure

(don't clean dust collection drawer)

3. Poor Maintenance Practices

Critical oversights:

Ignoring pressure differential gauges

Delaying filter changes to "save money"

Not emptying collection bins regularly

Outcomes:

30-50% reduction in airflow

Fire hazards from accumulated dust

Voided equipment warranties

The Professional Solution: LW12 Series Laser Smoke Collector

Why Choose LW12 Series System:

Perfect for various laser machines:

Fiber lasers (3000W-30000W)

Mixed-material processing

Key features:

✔ Adaptable connectivity for different machine brands

✔ Smart monitoring with automatic filter cleaning

✔ Explosion-proof option for aluminum cutting

✔ Energy-efficient operation reduces costs

Power Space Expert Support

Comprehensive service includes:

Free consultation: Provide your laser model and materials

Custom solution: Perfectly matched laser cut smoke collector

Complete package: Ducts, fittings, and installation guidance

Maintenance training: Keep your system running optimally

If you have any inquiry (Choose suitable model, Dust removal solution and so on), please feel free to contact us!